Three treatment methods for stainless steel screws

13 Nov,2023

Under normal circumstances, in stainless steel standard parts, the heat treatment of stainless steel screws is determined according to the hardness of the screw itself. The commonly used heat treatments are: tempering heat treatment, chemical heat treatment and local heat treatment.The first two heat treatments are designed for the whole, and the heat treatment method is for the local treatment. No matter which heat treatment method is used, it is very important for the screw itself.The heat treatment methods used for different hardness are also different.Even if it is the same heat treatment method, the hardness is different, and the selected ruler and hardness standard are different.

Three ways to deal with screws:

1. Tempering heat treatment: Tempering heat treatment is mainly carried out by induction heating or flame heating. You can use two hardness testers to test the hardness of the screw, and then decide which standard heat treatment to choose. The two hardness testers are Vickers hardness tester and Rockwell hardness tester.In addition to hardness to determine the thickness, you can also choose from the thickness of the surface heat treatment. For the unit used to process or use a large number of surface heat treatment workpieces, choose a Vickers hardness tester; when the surface heat treatment hardened layer is thicker, a Rockwell hardness tester can also be used.Different tempering and heat treatment standards can be interoperable, because their conversion values are internationally recognized. After choosing a hardness tester, different scales should be selected, namely HRA scales and HRC scales.

2. Chemical heat treatment: Another heat treatment method for screws, chemical heat treatment, is mainly to penetrate the atoms of one or more chemical elements into the surface of the workpiece, thereby changing the chemical composition, organization and properties of the surface of the workpiece. What effect can be achieved after chemical treatment?After quenching and low temperature tempering, chemical heat treatment can make the surface of the workpiece have high hardness, wear resistance and contact fatigue strength, and the core of the workpiece has high toughness.

3. Local heat treatment: According to the requirements of different stainless steel screws, not all screws require overall heat treatment, and some screws only require local heat treatment. This is the local heat treatment method.If this kind of local heat treatment requires high local hardness for those parts, local quenching and heat treatment can be carried out by induction heating. Such parts usually have to be marked on the drawing. The location of the local quenching and heat treatment and the local hardness value.

Keywords:

Flange

Related Blog

GJY A105N Fully Meets New CSA Requirements

24 Apr,2025

30 Apr,2025

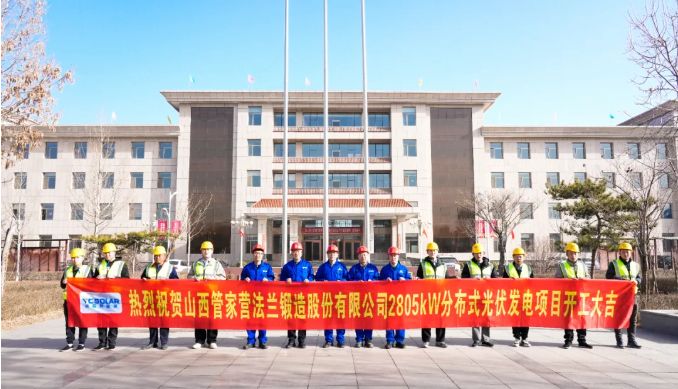

Green starts, shared a sunny future——The 47th 'Tree Planting Day' is different

12 Mar,2025